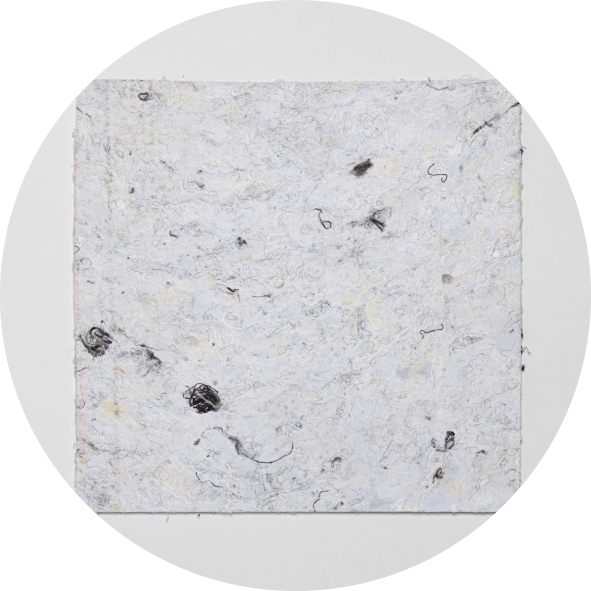

Airlay

Airlay is made from high-quality fibers, that are sourced from post-consumer textiles, ensuring a minimal carbon footprint and with almost endless variation possibilities, making it highly customizable. It can be used in a variety of industries, including automotive, interior design, construction, and consumer products.

USABILITY & BENEFITS

The usability & benefits of Airlay are many. For the automotive industry, major benefits result from its highly versatile ability to be molded into any form and shape. Its light-weight, super strength, abrasion stability, thermal protection, flame resistance, air filtration, and the ability to combine it with other materials such as carbon fiber makes it the perfect product solution.

In the interior industry and in consumer goods design, Airlay offers benefits such as dimensional stability, great acoustic characteristics, color stability, high tear resistance, durability, and ease of use in terms of cutting, gluing, sewing, trimming, and laminating.

Our commitment to sustainability is reflected in every aspect of our product, from the materials we use to the production process itself. By choosing Airlay you are not only making a responsible choice, but you are also introducing a “one material fits many” solution to your product range.

So, whether you are an interior designer / furniture manufacturer looking for a sustainable and versatile material to incorporate into your products, or a car-manufacturer looking for an innovative and eco-friendly filling material, or moldable-alternatives, our product is the perfect solution.

Soundproofing Panels | Layered Airlay

Architectural Elements | Layered Airlay

Acoustic dividers & insulation | Airlay

Furniture padding | Layered Airlay

Soundproofing Panels | Layered Airlay

Architectural Elements | Layered Airlay

Acoustic dividers & insulation | Airlay

Furniture padding | Layered Airlay

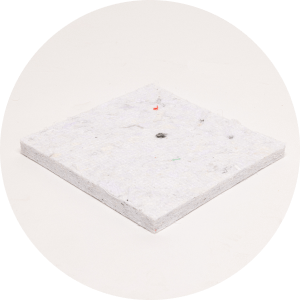

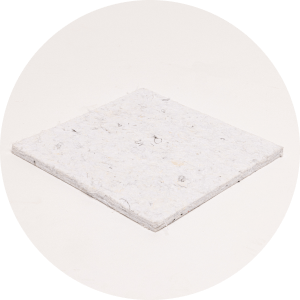

VARIATIONS & CUSTOMIZABILITY

The variation and customization possibilites are endless – whether you are looking for a specific range of colors, various thicknesses, a specific mold-strength or the possibility to incorporate other fibers into the raw pulp – get in touch with us to make your customization wishes possible. We can meet any of your specific design and implementation needs.

THICK

medium

thin